In my last post I brought you up to speed on the rebuild of Plume Projectile. Today was Greenpower afterschool club and the year 10's helped to reduce the width of the back axle (affectionately known now as the 'Baxle') by some 170mm. It now looks less ungainly and should also be a lot less prone to bending.....

|

| View from the rear of the new, narrowed 'Baxle' |

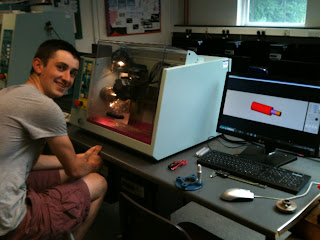

In addition to this sterling effort, our tame 6th former, Tom, has been hard at work all day sorting out our little Boxford CNC lathe. The feed rates and chuck speeds as supplied from Boxford were more than ambitious and were the cause of many a horrid graunchy noise during manufacture. Tom and I have now rectified this and Tom has managed to produce the first of a run of 8 aluminium spacer 'top hats' designed to spread the load and prevent us from crushing the delicate core of the aluminium honeycomb chassis material.

|

| Tom, hard at work on the CNC lathe! The End Result:

NICE!!!!

|

No comments:

Post a Comment

Note: only a member of this blog may post a comment.